Air atomising nozzles

Whilst not strictly a spray pattern, air atomising nozzles have many unique spray properties which means this family of versatile nozzles need their own section on our website.

In direct pressure nozzles the fluid is broken up (atomised) into droplets by either impact on a surface or by the shearing force caused by passing the liquid through a shaped orifice. In both cases the energy required for the atomisation comes from the potential energy of the fluid itself. Essentially the energy available for atomisation is a function of fluid pressure.

In air atomising nozzles pressurised air (or other gas) is used to impact upon the fluid being sprayed. The impact of the gas causes the fluid to break apart into a fine spray. This means that the energy required for atomisation is no longer dependent on fluid pressure because of which very fine sprays can be produced at low fluid pressures. This allows for very fine, low volume sprays to be delivered.

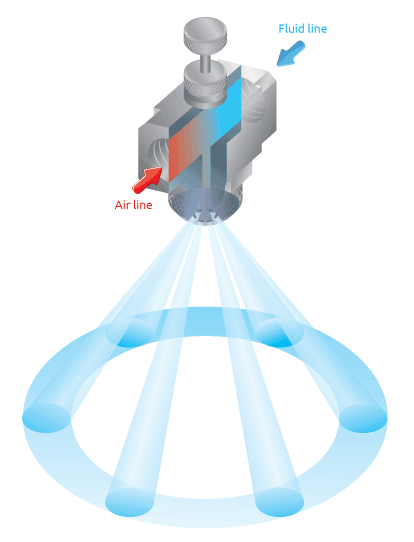

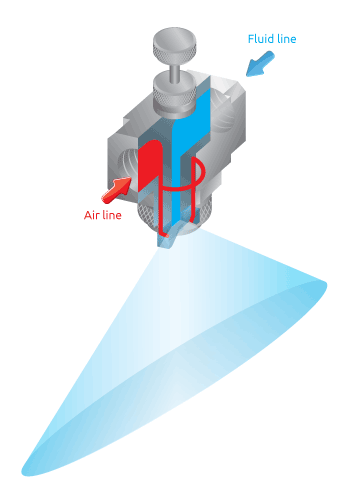

Images below show internal mix nozzles (L) and external mix nozzles (R)

Controlled spraying

The presence of pressurised air means a greater degree of control can be exerted over the spray. By varying air pressure the shape and level of atomisation can be changed without affecting fluid pressure. The SAM advanced air atomising nozzle takes this control a step further by introducing two separate air feeds, one controls the spray pattern and the other controls the atomisation. Further levels of control can be achieved by using the air feed to rapidly shut off spraying. If linked to a suitable control system, air atomising nozzles can be made to rapidly shut on and off many times a second. This allows for very precise spraying.

Air atomising nozzle variants

Details on the different types of air atomising nozzles in the SNP range can be found by clicking on the items in the blue menu to the right hand side of this page. Or direct links to the datasheets can be accessed by clicking on the boxes below.